Products

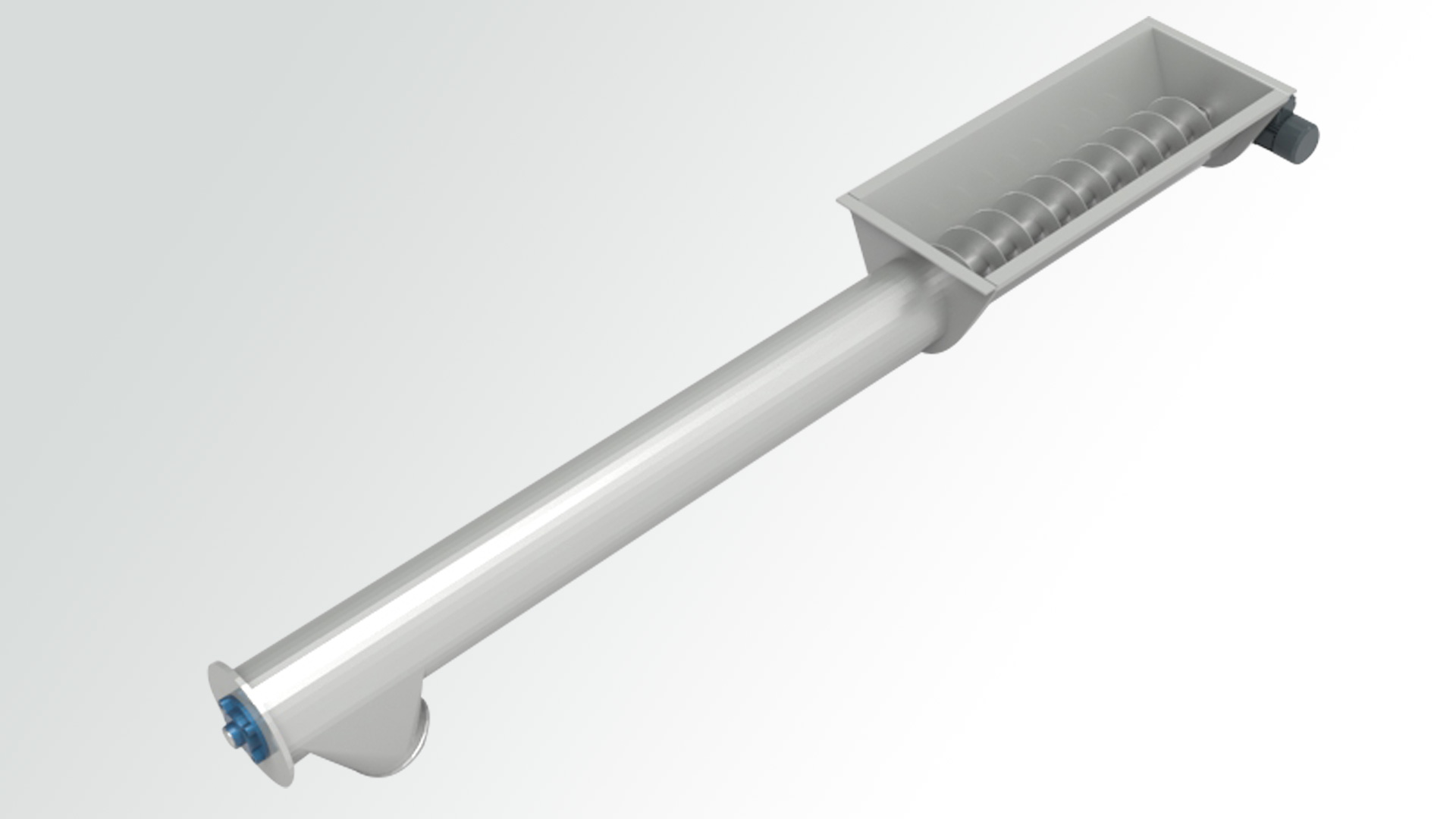

The screw conveyor produced by CaReDi is used for the transport of bulk material with medium-low capacity.

Its strength is simplicity, in fact it consists of a helical coil, in carbon steel, stainless steel or with high abrasion resistance, welded in its internal diameter on the crankshaft. Usually at one end there is a flanged support, and at the opposite the gearmotor is applied which can be with parallel or perpendicular axes, with hollow shaft. The machine can be equipped with speed control and anti-clogging sensors.

The rotary motion ensures the advancement of the product which receives the thrust from the helix of the coil itself. The pitch of the loop is chosen according to the type of material to be transported. Depending on the use, the coil can be constant or with variable pitch. The helix can also be left-handed or right-handed depending on the direction of transport (there is also the solution with the intermediate feeding of the material which provides for the coexistence of the two cases). The control unit consists of a gearmotor, generally located on one end of the machine, which transmits motion to the crankshaft directly or by means of a pinion and chain or belt and pulley transmission. The entry of the material to be transported takes place in the upper part of the screw conveyor, and is usually guaranteed by a loading mouth designed to receive the material and convey it inside the conveyor. The material is discharged by gravity or by thrust through the unloading openings located in the lower part of the machine. In the case of two or more exits, it will be necessary to use shutters for the management of end users.

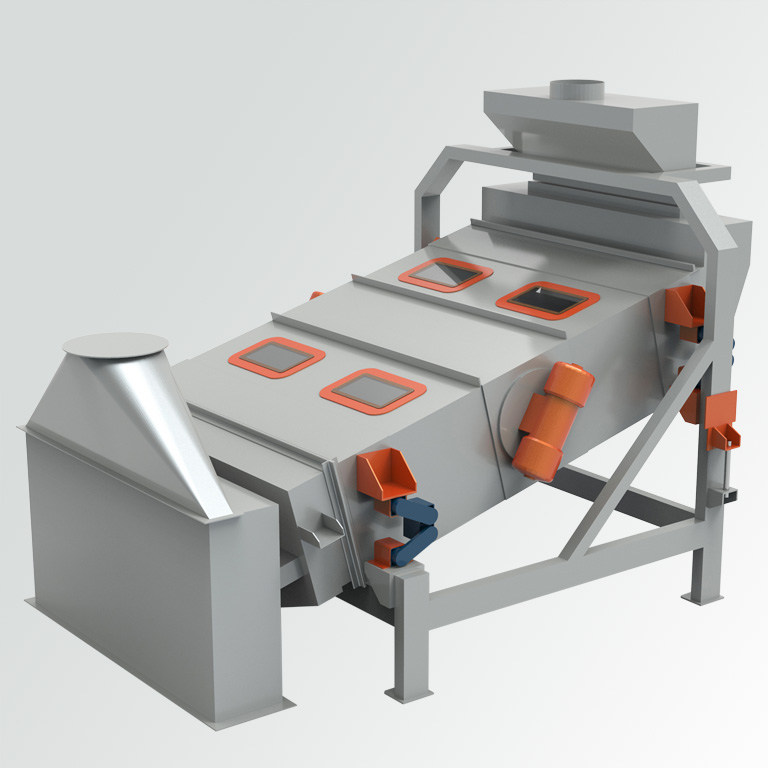

The auger can be configured according to the use for which it is intended (conveyor, extractor, mixer) and can have one or more axes (single, double, quadruple) and multiple longitudinal boxes (with intermediate supports).